RMM-20 UHL1

The device is designed to protect the insulation of overhead power lines with 50 Hz voltage from 6 to 20 kV from atmospheric surges and to protect electrical equipment from lightning or switching surges.

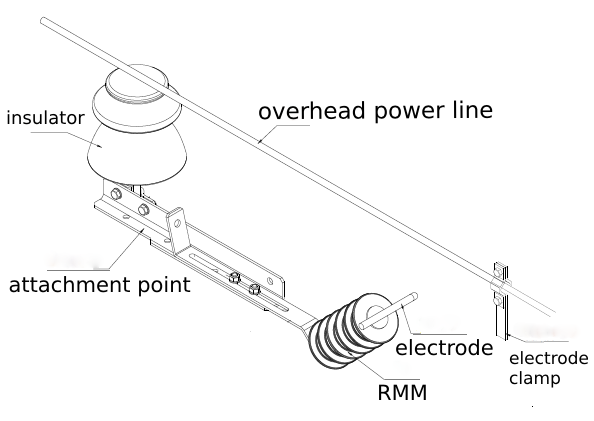

The device is a suspension-supported protective device, consisting of a grounded protective element – a multimodular arrester (RMM), an external air spark gap between two electrodes, one of which is connected to the RMM, and the other to the current-carrying (phase) wire of the overhead line and attachment point of the device on the overhead line in the form of a set of metal parts and hardware. Schematically, the location of the device on the overhead line is shown in pic 1.

Pic.1. RMM device location on the overhead line.

RMM consists of modules strung on a supporting fiberglass rod. RMM modules are made in the form of round silicon rubber plates containing metal electrodes inside. The modules on the carrier rod are assembled in a way that local spark gaps are formed between adjacent plates. The rod with modules is crimped on both sides with end fittings. At the ends of the end caps there are threaded holes for the external electrode and the attachment point. The general view of the RMM is shown in pic 2.

Pic.2. General view of RMM device.

The device is installed on the overhead line using the mount parallel to the insulator, on the traverse element or the connecting fittings of the insulator, electrically connected to the ground. An air gap of 50 – 70 mm is set between the electrode of the device and the electrode fixed on the wire.

Using the electrodes supplied with the device, a spark gap is created between:

– on intermediate supports with insulators of the ShF, OLF or OLSK type – with an electrode fixed on the RMM end cap and an electrode fixed on the wire with a piercing clamp;

– on anchor and intermediate supports with suspended polymer or glass insulators – between the electrode fixed on the RMM end cap and the electrode mounted on the polymer insulator end cap, or on the elements of linear fittings that are part of the insulating suspension of glass insulators from the side opposite to the one where it is fixed RMM. In this case, the metal parts supplied with the device are used as the second electrode.

The wire-mounted electrode is a plate with a piercing clip for mounting on both insulated and bare wires. It is allowed to install the RMM element at an angle of up to 45 degrees to the vertical.

The design of the electrodes and the method of mounting the device on the overhead line make it possible to keep the spark gap constant under any weather conditions.

When an overhead line wire is exposed to induced overvoltages caused by lightning discharges near the overhead line or direct lightning strikes, an external spark gap between the RMM and the wire first breaks through, and then spark gaps between the modules in the RMM. RMM carries out the exhaust of hot gas into the surrounding atmosphere, as a result of which the gas jets are cooled and the accompanying current is extinguished.

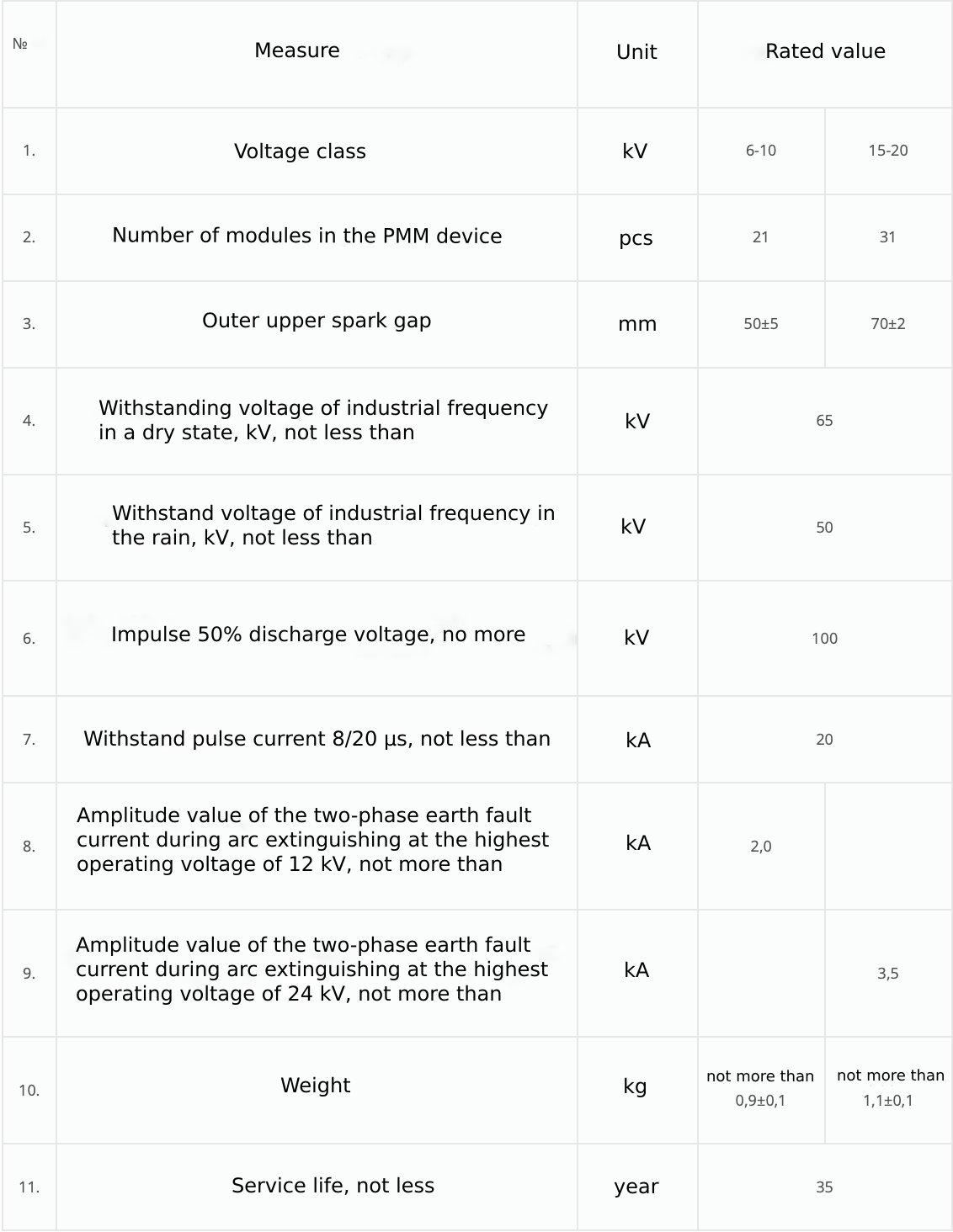

RMM specifications

Multimodular arresters provide for installation on overhead lines with any type of supports and insulation.

Devices can be installed one per tower with phase sequence. This scheme is used with a span of overhead lines up to 80 m. RMM can also be installed in three products for each support, i. one for each phase. This scheme is used when the overhead line span is more than 80 m.

The use of the device under development makes it possible to create reliable protection of overhead lines with a voltage class of 6-20 kV from atmospheric (lightning) surges, which has a low cost in production and operation.